Accumold unveils groundbreaking, thin-walled cannula at MD&M East conference

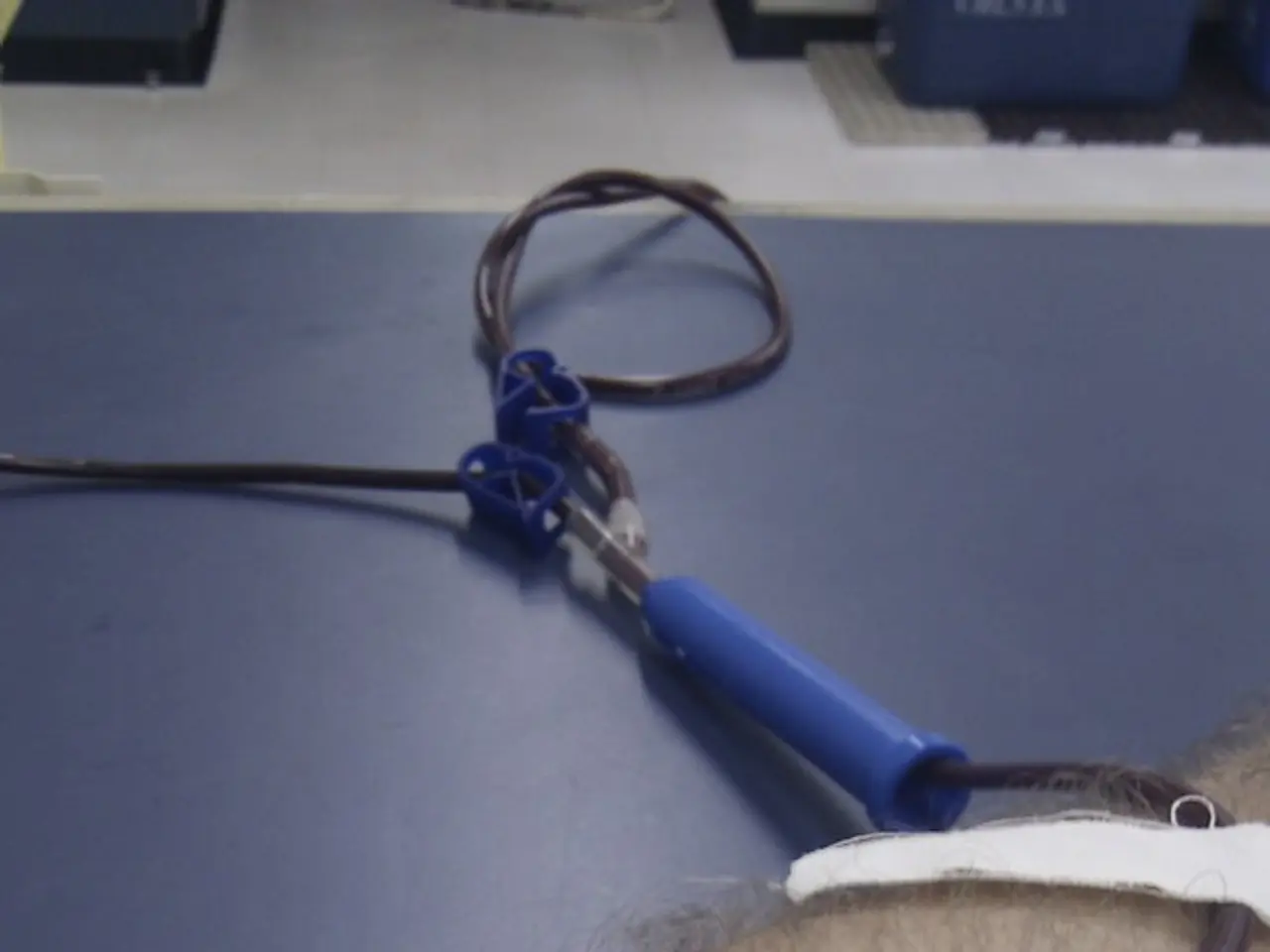

In a groundbreaking development, Accumold has achieved a significant milestone in the production of thin-walled cannulas, making it possible through a single moulding process. This advancement, a testament to the company's expertise in micro moulding for medical-grade materials, is set to transform the medical industry.

Accumold's innovation in micro moulding for medical devices is gaining recognition, with recent articles such as "Navigating the complexities of micro moulding for medical devices" and "A lesson in injection moulding of thin wall cannulas" delving into the challenges and solutions in this field.

At MD&M East 2025 in New York City from May 20-22, Accumold will showcase its latest innovations in micro moulding for medical devices. Attendees can visit Booth 551 to meet the technical team, view micro moulded samples, and discuss how micro moulding for medical devices can accelerate development and reduce time to market.

The company's expertise extends beyond the aforementioned materials, with Accumold working with a variety of materials suitable for surgical tools, diagnostic kits, drug delivery systems, and more, including PEEK, LCP, Polycarbonate, Polypropylene, and Pebax. Visitors to Booth 551 can explore how advanced moulding techniques enable smaller, smarter medical components.

The key to these advancements lies in precision micro injection moulding, innovative machinery and technologies, and material and process enhancements. New micro moulding processes maintain the integrity of complex, miniature designs with tight tolerances, crucial for thin-walled cannulas. Machines like the fifth-generation Zhafir series, equipped with technologies like Precision Dosing Control (PDC), Inertial Filling Control (IFC), and Optimal Force Control (OFC), improve production stability and precision in micro moulding.

Use of biocompatible, medical-grade materials combined with precision silicone micro moulding allows for the fabrication of tiny, thin devices with excellent performance and durability. This convergence of advanced micro moulding technology, sophisticated machinery, and biocompatible materials is transforming the production of thin-walled cannulas by enabling mass production of high-precision, complex, and tiny medical components.

Brett Saddoris, Technical Sales Manager at Accumold, stated that this is a major step forward for minimally invasive devices. He mentioned that Accumold works closely with engineers to turn complex designs into scalable, high-precision components. This technique allows for wall thicknesses as low as 0.1 mm and supports volumes of up to 40 million parts per year per cell.

These micro moulding advancements enable the miniaturization and increased complexity of medical devices, supporting less-invasive procedures with improved outcomes. Thin-walled cannulas made with micro moulding offer enhanced precision and reliability in applications like intravascular interventions and drug delivery, reducing patient trauma and recovery times.

In conclusion, Accumold's advancements in micro moulding for medical devices are revolutionizing the production of thin-walled cannulas, paving the way for smaller, smarter, and more efficient medical components. This fuels innovation in minimally invasive medical devices, improving clinical performance and expanding treatment options in the healthcare industry.

References:

- Accumold

- Zhafir

- Freudenberg Medical

- "The role of micromoulding in wearable diabetes devices"

- The transformation in the medical industry is being fueled by Accumold's expertise in healthcare manufacturing, specifically their innovative use of medical plastics in micro moulding for medical devices.

- The use of cutting-edge technology, such as the Zhafir's Precision Dosing Control, Inertial Filling Control, and Optimal Force Control, is instrumental in maintaining the precision required for the production of thin-walled cannulas.

- These advancements in medical devices not only support less-invasive procedures but also contribute to the broader health-and-wellness sector by improving outcomes for various medical-conditions, leading to a more efficient and innovative healthcare manufacturing landscape.